Cangzhou Qianjinyawa Machinery Manufacturing Co., Ltd.

Payment Terms: TT or LC

Ref Price : US $6,500-14,000 / Set

Supply Capability : 20 Set/Sets per Month Cold Forming Machine Metal Machine Sheet Rolling Metal Machinery

Loading Port : TianJin

Inquire Now Quality Product

Quality Product

Credit Purchasing

Credit Purchasing

Credit Rating

Credit Rating

Timely Delivery

Timely Delivery

Credit Services

Credit Services

Quick Details

Condition:

New

Type:

Tile Forming Machine

Tile Type:

Colored Steel

Use:

Roof

Production Capacity:

10-15M/min

Place of Origin:

Hebei, China (Mainland)

Brand Name:

QJ

Model Number:

YX30-200-1000

Power(W):

5.5kw

Voltage:

380V 3Phase 50Hz

Dimension(L*W*H):

10m*1.85m*1.5m

Weight:

6.5tons

Certification:

SGS TUV

Warranty:

18 months

After-sales Service Provided:

Engineers available to service machinery overseas

Under frame:

400 H steel

Sidewall:

16mm

Shaft material:

45# steel with finish turning

Roller material:

45# steel with chromium plate

Forming station:

20

Name:

Cold Forming Machine Metal Machine Sheet Rolling Metal Machinery

Chain wheel:

1 inch

Chromium plate thickness:

0.05mm

Control cabinet:

Delta PLC

Cutting head material:

Cr12Mov

Packaging & Delivery

Packaging Details

Cold Forming Machine Metal Machine Sheet Rolling Metal Machinery

1 Most of the machine is nude. 2 Rolers and shafts will be packed with waterproof package. 3 Machine will be painted oil against rust during shipping 4 The whole machine will be loaded in a 20-foot container, and it will be fixed together with container by wire rope. More machines together,much more cheap sea freight price.

Delivery Time

30 days after we get deposit

Technical parameters

|

No. |

Cold Forming Machine Metal Machine Sheet Rolling Metal Machinery |

|

|

1 |

Suitable material |

PPGI/Aluminium sheet/galvanized sheet/various sheet plates |

|

2 |

Thickness of coil sheet |

0.2-0.8mm |

|

3 |

Coil width |

1250mm |

|

4 |

Cover width |

1000m |

|

5 |

Material of main frame |

400H steel |

|

6 |

Diameter of Soild shaft |

45mm, high grade 45# steel |

|

7 |

Roller |

Quenched and tempered treatment, hard chrome coated 0.05-0.07mm |

|

8 |

Thickness of middle plate |

14mm |

|

9 |

Forming station |

18stations |

|

10 |

Drive type |

By chain(1.0 inch) link bearing model 6210 |

|

11 |

Power of main motor |

5.5kw with Cycloidal reducer |

|

12 |

Power of pump station |

4kw |

|

13 |

Forming speed |

About 8-10m/min |

|

14 |

Hydraulic cutting |

Controlled by PLC |

|

15 |

PLC |

DELTA(TAIWAN)/Mitsubishi |

|

16 |

Material of razor blades |

Cr 12, quenching 58-62℃ |

|

17 |

Frequency converter |

It has the advantage of slowing down before cutting, to ensure the length accuracy(±1mm, far better than industrial standard ±3mm). |

|

18 |

Switch |

CHNT |

|

19 |

Transducer |

SAJ |

Remark:

Above parameters are standard, we can design and make some change exactly according to your

requirements.

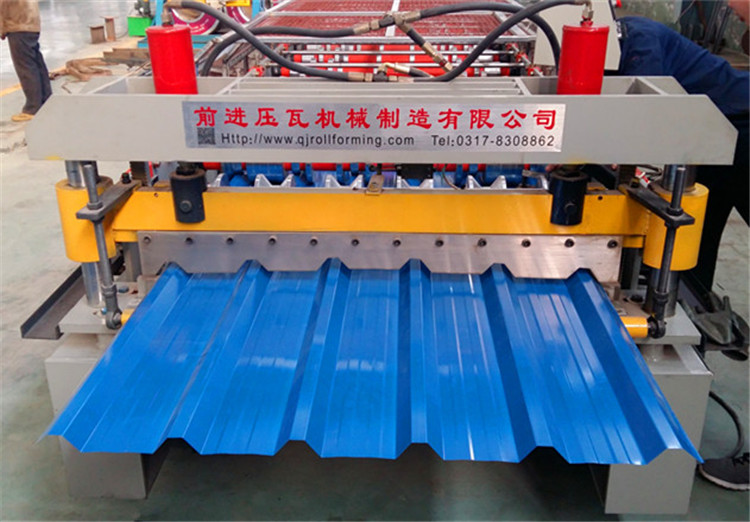

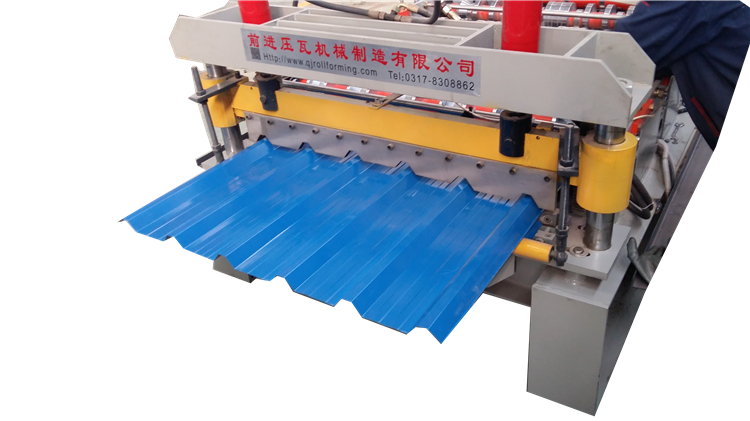

Panel profile sample

Hand pre-cutting and feeding device

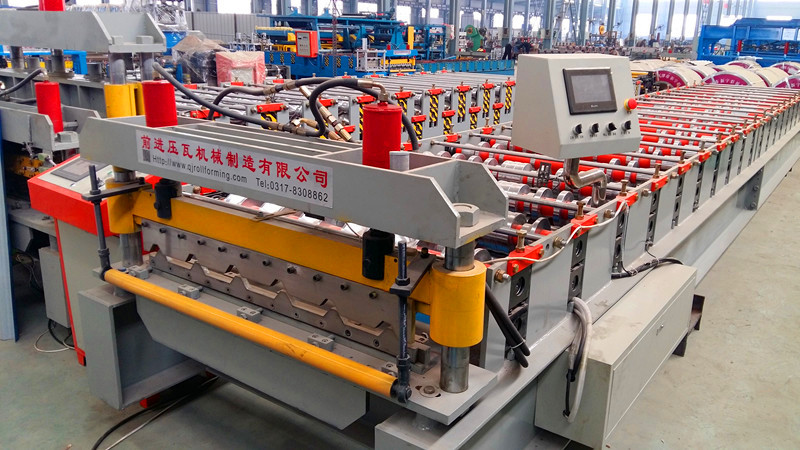

Roll forming system

Counter system for sheet length

Hydraulic cutting system

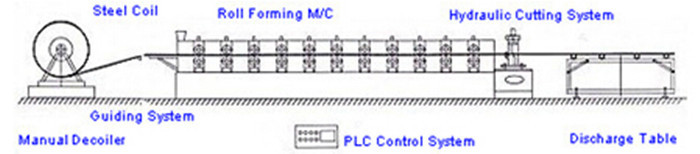

Production Flow

Manual decoiling→sheet guilding→roll forming→hydraulic controlling length→automatic cutting→

finished product supporting

Accessories

Spare parts ( for free)

The quick-wear parts are sent to you together with the machine.

chain 2pcs; hydraulic oil pipes 2 pcs; electromagnetism valves:1pc;

limit switch 2 pcs; counter 1pc; relay 2 pcs; Swith 1 group.

Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd.

We have been devoted to designing, developing and manufacturing pressure equipment for 10 years. We have high quality professional teams, skillful talents, strong technical force, strong and independent research and development capabilities, advanced production equipment and a perfect after-sales service system.

Our main products are all construction equipment ,such as color steel roofing sheet roll forming machines, C&Z purline machine, steel roof tile roll forming machines, floor deck forming machines, EPS sandwich panel roll forming machine, highway guardrail forming machine, shearing machine, bending machine, slitting machine.