- Home/

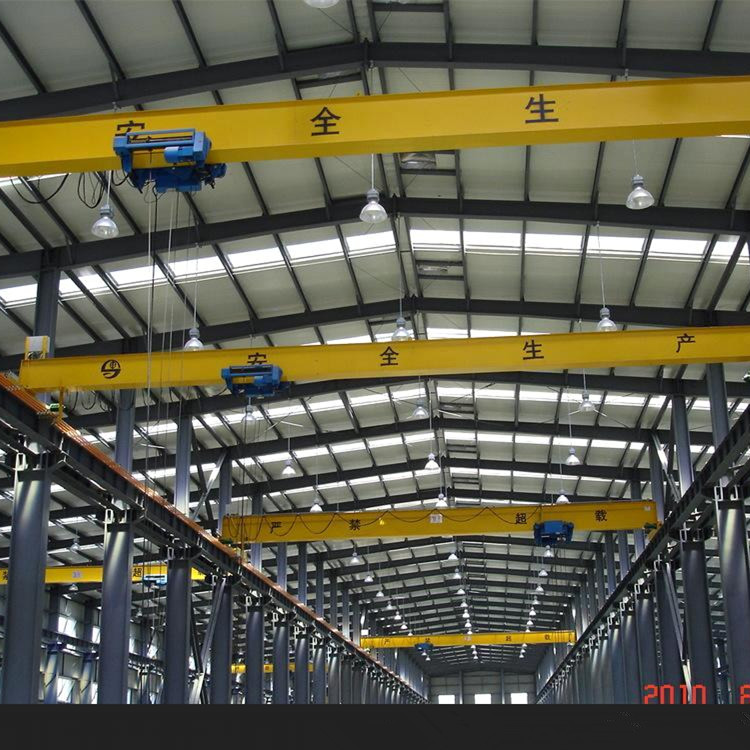

LD Explosion Proof Single Girder Bridge Crane 2T 3T 5T

Payment Terms: TT or LC

Ref Price : 10000-50000 USD/TON

Sino-Sources Service Pledge

-

Quality Product

Quality Product

-

Credit Purchasing

Credit Purchasing

-

Credit Rating

Credit Rating

-

Timely Delivery

Timely Delivery

-

Order On-line Tracking

Order On-line Tracking

-

Credit Services

Credit Services

Quick Details

-

Material:steel

LD Explosion Proof Single Girder Bridge Crane 2T 3T 5T

The design, manufacture, installation and operation of LD Explosion-Proof Single Girder Overhead Crane meet the requirement of JB/T 10219 standard. This explosion-proof single girder overhead crane is equipped with HB explosion-proof wire-rope electric hoist which is a light type equipment. With explosion-proof grade of ExdIIBT4 or ExdIICT4, this explosion-proof single girder overhead crane can be used at workshops with initiation ability lower than IIB or IIC, and danger area 1 or 2 (according to GB3836.1-2000). The explosion-proof performance of motor and all electric equipment meets the requirement of GB3836.2-2000.

|

Lifting Capacity |

T |

1t |

2t |

3t |

5t |

10t |

16t |

20t |

||

|

Span |

m |

7.5~22.5m |

7.5~31.5 |

|||||||

|

Speed |

Lifting |

MD1 hoist |

m/min |

8/0.8 (7/0.7) |

3.5/0.35 |

|||||

|

CD1 hoist |

8 (7) |

3.5 |

||||||||

|

Traveling of electric hoist |

20 |

20 |

||||||||

|

Traveling of crane |

20/30 |

20/30 |

||||||||

|

Wheel diameter |

Φ270 |

Φ370 |

||||||||

|

Width of trail |

37~70mm |

37~70mm |

||||||||

|

Operational Model |

Remote control; Ground handle |

Remote control; Ground handle |

||||||||

|

Working Duty |

A3 |

|||||||||

|

Power Supply |

Three-phase A.C. 380V, 50Hz |

Three-phase A.C. 380V, 50Hz |

||||||||

-

Mechanism Parts

1. Single girder, made by the high quality I steel and high quality U-shapped slot into composition

2. Material Q235B or Q345B(similar as Fe37 or Fe52)

3. End beam is welded with rectangular tubes or good steel

4. Main girders connected with bolts

5. Crane traveling use respective drive

6. QS trinity-drive system or traditional drive by motor and reducer

7. Assembly and adjustment is rapid, simple

8. Use LD single girder special wheel, light and strong versatility

-

Electric Hoist

1. Lifting motor: Tapered rotor three-phase asynchronous braking motors

2. Reducer: Three-level dead axle helical gear rotating body, Gear and the axle made by alloy steel after heat treatment, high intensity

3. Rope drum: Made of cast iron or seamless steel tube, light weight, transmit the dynamic force by splines.

4. Steel wire rope: It uses GB1102-74(6*37+1) hoist steel wire rope which is durable in use

5. Forge with special steel: thrust ball bearing connect with casing through hook and beam to make the hook operate freely.

-

Electric Equipments

1. Trolley conductor or angle steel conductor power supply

2. Hoist and crane separately control, move separately or together

3. Flat cable or special cable power supply for electric hoist

4. Galvanize slide and cable trolley, smoothly moving, appearance is aesthetics

5. Electrical non-contact speed regulation control module

6. Operation, hoisting, the point start are very smoothly

7. Power leading has both methods of current collector and flexable cable

|

|

|

-

Safety Protection Devices

1. Locked fall-proof reducer

2. Outdoor hoist with rain-cover

3. Alarm indicator lights

4. Infrared anti-collision

WeiHua Overhead Crane Manufacturers Related Products

|

|

18 Ton Electric Hoist Single Girder Eot Crane

|

5 Ton HD Type Single Girder Overhead Crane

|

Weihua Gantry Crane and Other Popular Cranes

The products meet the factory, workshop, port, mining, waste disposal, goods scattered, petrochemical, aerospace, military and other industries of universal bridge crane, overhead crane, EOT crane, door crane, universal gantry crane, rubber tyre and rail mounted container gantry crane four link type portal crane, quayside container crane, crane, crane hook, mining grab crane, gantry crane, ship loader, grab bucket ship unloader, stacker reclaimer, dredger, mobile platforms and other types of hydraulic crane technical requirements.

WEIHUA Crane Manufacturer and Supplier founded China’s first crane design R & D team and there are 500 personnel now, developed the anti-swing technology independently and has obtained more than 100 patents. Weihua has been the post-doctoral scientific research workstation of Henan Province for four consecutive 4 years. Weihua has its own independent laboratory and has passed the CNAS certification, it is the only one industrial crane production and testing base appointed by government.

WeiHua own professional engineers and technicians for Quality Control (the Standards are in terms of pre-production, producing process, after-production.)

1. Senior purchasers source parts as electric devices and menchanical parts, then QC inspect the spare parts before entring the warehouse.

2. During producing and assembly, senior QC proceed to inspect.

3. Senior engineers debug and test the machines after customers order and before shipment.

|

|

|

|

|

|

|

|

|

|

Further more, as the designated supplier of Jiuquan Satellite Launch Base, Weihua accelerated the launch of Chang'e successfully.

Unique Weihua Crane Services

1. Fast and timely response for any overhead industrial cranes inquiry.

2. Free custom design service for any our sale of industrial cranes

3. Quite competitive price that usually fifth less than the other industrial crane sales manufacturers

4. Anytime to receive your visit to our cheap industrial crane factory.

After-sale service of industrial cranes

1. Offer you high quality industrial hoist and crane, which made by advanced technology and professional industrial cranes engineers.

2. Free industrial cranes for sale operation training until you get it clearly and totally though many ways, such as the internet, face to face, or phone and email.

3. One year free maintenance and lifetime maintenance for your overhead industrial cranes

4. Free test for your industrial cranes on the basis of related standard, and send you the industrial cranes test certification.

5. Free and cheap industrial crane delivery suggestion from our rich sales managers.

Questions:

-

1. How long is WeiHua products warranty?

We afford 12 months of quality warranty period after customers buy from us.

-

2. What's the warranty content?

We will provide free onsite service on repairing and replacing malfunctioning or damaged parts which are proved to be our manufacturing quality defects within the warranty period.

-

3. What if is out of warranty period?

-

(1) We will provide chargeable onsite service on repairing and replacing malfunctioning or damaged parts after the warranty period.

-

(2) We will supply dispensable parts preferentially for a long period.

-

(3) We will keep in touch with customers to track and survey of the product.

-

-

Contact:

Skype: paulpaul120481

Mobile: +86 18622088833 (whatsapp,line)

Email: info@sino-sources.com

Weihua Group, a leading crane manufacturing company in China, was Founded in 1988. We has been committed to heavy machinery researching and marketing.

The main product covers shipbuilding gantry crane, lifting machinery, port container crane, heavy mining machinery and construction machinery, etc. The whole coverage of Weihua Group is 3,420,000 m2 with 6,800 employees.

Weihua adheres to scientific and technological innovation and owns a 600-people R&D team, 494 patents, CNAS laboratory, etc. For the cranes, Weihua have made many breakthroughs which include anti-sway crane system, CNC high precision positioning crane system, self-climbing crane for wind power maintenance and so on.

In recent years, Weihua cranes have been employed to serve China's Aerospace Engineering projects such as launching of Shenzhou spacecraft, Long March carrier rockets and Tiangong space laboratory. You can also find Weihua products in the fields of manufacturing, metallurgy, nuclear power, railway,port, petrochemical and wind power.

Weihua products also find its places in the global markets and won much praise from108 countries like America, Japan, Russia, Singapore, Korea, Thailand, Malaysia, Mexico, etc.

Our success comes from customers' success. Welcome to Weihua.

Collection

Collection